AIR, OIL, CHARGE, TUBE & SHELL COOLERS FOR ALL HEAVY DUTY MACHINERY

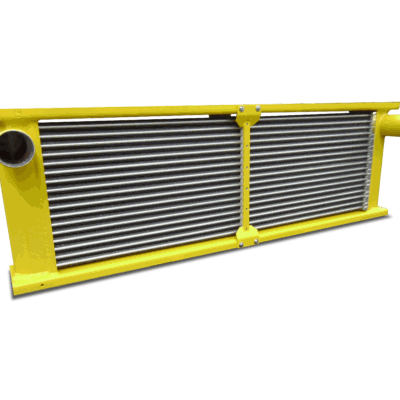

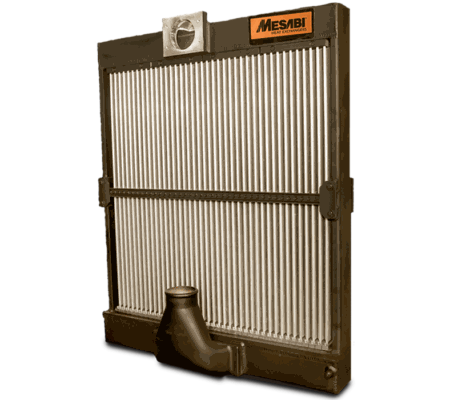

AIR TO AIR / OIL COOLER

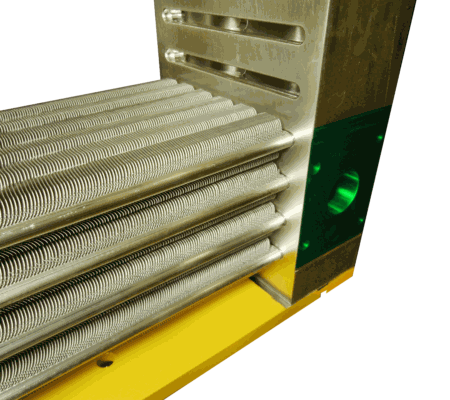

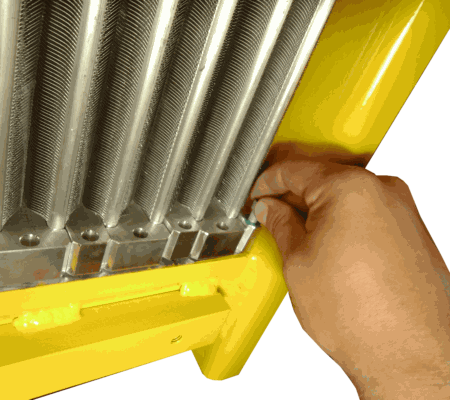

S FIN COOLERS

FOR HYDRAULIC AND COMPRESSOR OIL/AIR COOLING

PRESSURES: up to 600psi (4137 kPa)

S fin coolers are comprised of a single row of multi-ported high efficiency aluminium cooling tubes. The seal between the tube and header is held captive in header by a special process. Once a tube is in place, the seal is compressed to make a seal capable of withstanding the application specific pressures. MESABI® S fin charge air coolers and oil to air coolers can be designed to customer’s specifications.

FLEXIBLE CORE DESIGN

Individual cooling tubes held in headers with flexible rubber seals to absorb mechanical and thermal stresses that can cause conventional cores to leak.

FIELD REPAIRABLE

Seals allow any damaged tubes to be removed and replaced in the field using simple hand tools and often without removing the cooler from equipment.

EASY TO CLEAN

Clean with high-pressure air or water.

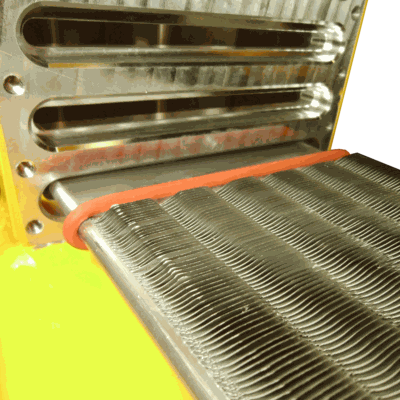

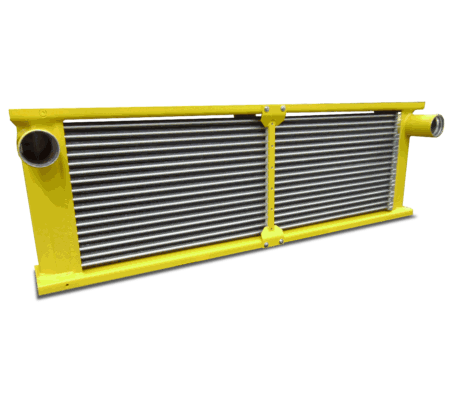

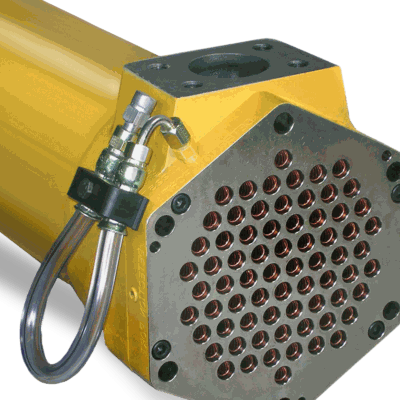

CSC™ HIGH PRESSURE COOLERS

FOR HYDRAULIC AND COMPRESSOR OIL/AIR COOLING

PRESSURES: up to 500 psi (3447 kPa)

Captured Seal Cooler™ coolers feature tube-to-header seals held captive in the header plate. Once a tube is in place, the seal is compressed to make a tube-to-header seal capable of withstanding tested pressures.

FLEXIBLE CORE DESIGN

Individual cooling tubes held in headers with flexible rubber seals to absorb mechanical and thermal stresses that can cause conventional cores to leak.

FIELD REPAIRABLE

Seals allow any damaged tubes to be removed and replaced in the field using simple hand tools and often without removing the cooler from equipment.

EASY TO CLEAN

Clean with high-pressure air or water.

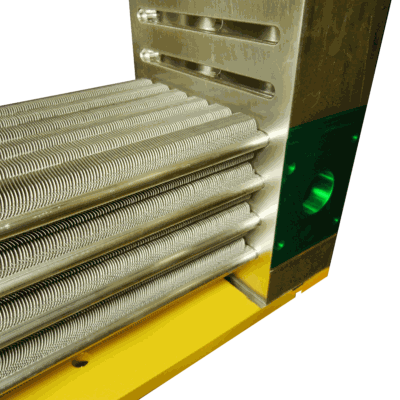

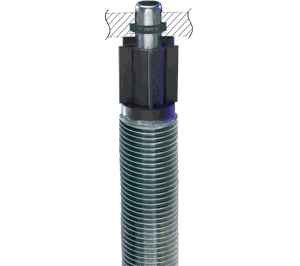

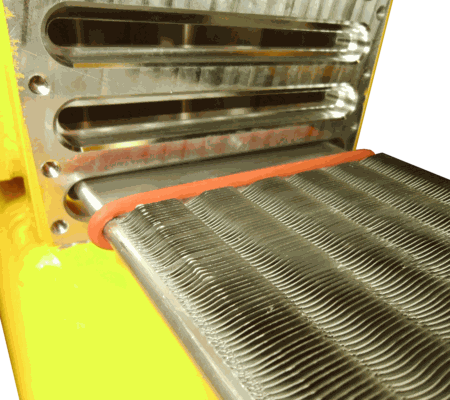

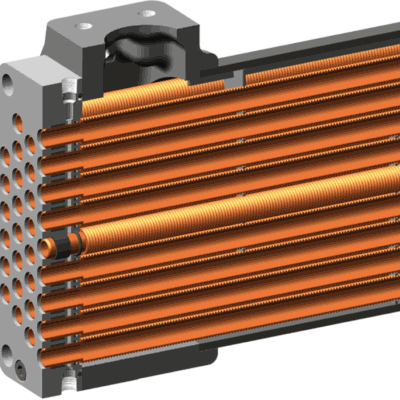

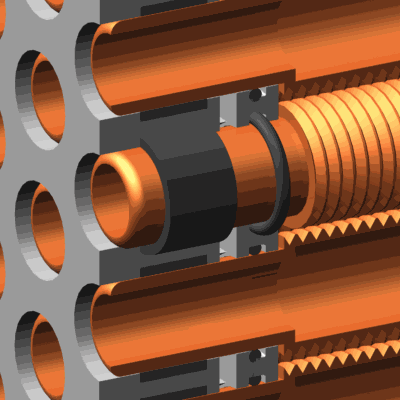

ALUMINIUM TUBE COOLERS

FOR HYDRAULIC AND COMPRESSOR OIL/AIR COOLING

PRESSURES: up to 175 psi (1207 kPa)

Standard aluminium tube coolers feature tubes with integral circular fining rolled from the tube wall. Turbulators are placed in tubes to increase heat transfer and are removable for cleaning.

FLEXIBLE CORE DESIGN

Individual cooling tubes held in headers with flexible rubber seals to absorb mechanical and thermal stresses that can cause conventional cores to leak.

FIELD REPAIRABLE

Seals allow any damaged tubes to be removed and replaced in the field using simple hand tools and often without removing the cooler from equipment.

EASY TO CLEAN

Clean with high-pressure air or water.

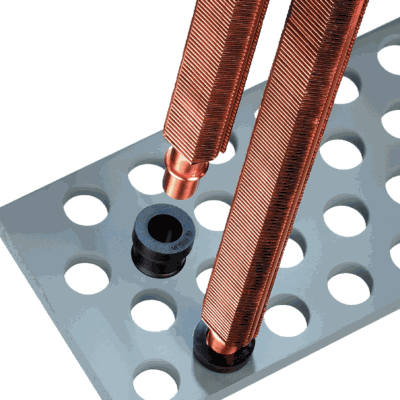

COPPER TUBE COOLERS

FOR HYDRAULIC AND COMPRESSOR OIL/AIR COOLING

PRESSURES: up to 150 psi (1034 kPa)

Copper tube coolers are similar in design to MESABI® engine radiators, but have internal turbulators. Designed for those applications where high efficiency is required and space available is limited.

FLEXIBLE CORE DESIGN

Individual cooling tubes held in headers with flexible rubber seals to absorb mechanical and thermal stresses that can cause conventional cores to leak.

FIELD REPAIRABLE

Seals allow any damaged tubes to be removed and replaced in the field using simple hand tools and often without removing the cooler from equipment.

EASY TO CLEAN

Clean with high-pressure air or water.

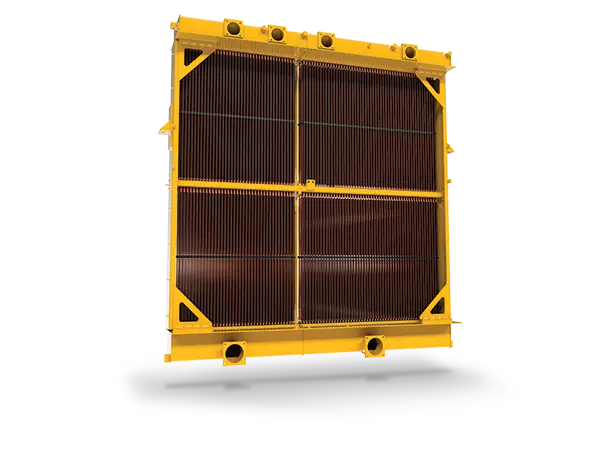

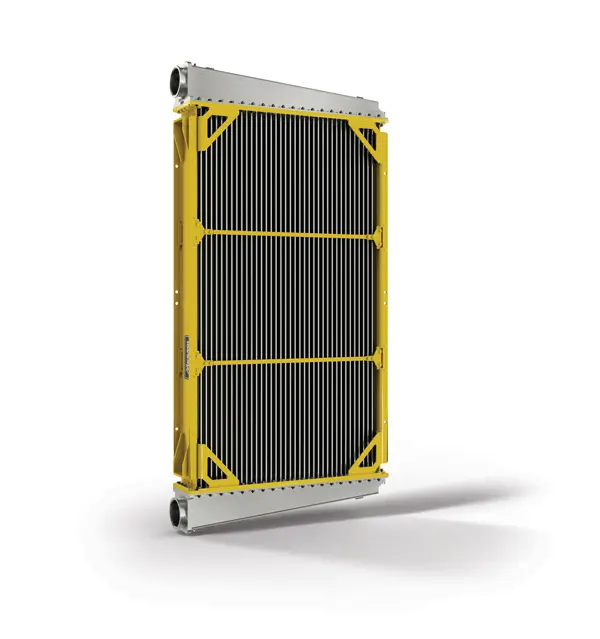

CHARGE AIR COOLERS

HIGH EFFICIENCY ALUMINIUM TUBE

FOR AIR-TO-AIR COOLING

Our highly efficient, durable charge air cooler designs include a core comprised of a single row of multi-ported high efficiency aluminium cooling tubes held in headers with flexible rubber seals to better absorb thermal shock and stresses.

Industry studies have shown header plate thermal fatigue failures and air tube leaks account for the majority of charge air cooler failures. The seal between our tube and header is held captive in header by a special patented process. Once a tube is in place, the seal is compressed to make a seal capable of exceeding charge air cooling pressures

FIELD REPAIRABLE

LIGHTWEIGHT

EASY TO CLEAN

WELDED FRAME

TWO SIZES: 3” AND 5.67”

18-MONTH WARRANTY AGAINST SEAL LEAKAGE

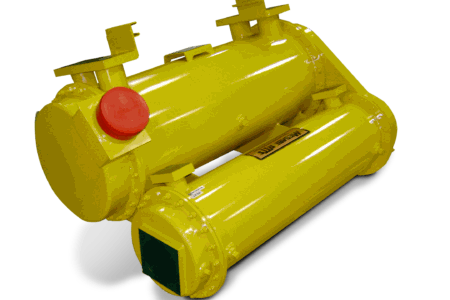

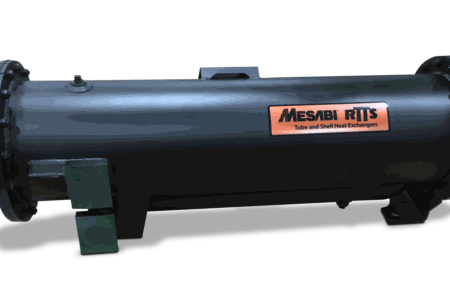

TUBE AND SHELL COOLERS

RTTS® COOLERS

FOR BOTH IN-PLANT AND MOBILE EQUIPMENT HEAT EXCHANGE: LIQUID TO LIQUID, LIQUID TO AIR AND AIR TO AIR EXCHANGE

INDIVIDUAL COOLING TUBES

Held in headers with flexible rubber seals to eliminate leaking.

TUBES ARE EASILY REMOVED

For cleaning or replacement if damaged, using simple hand tools.

LARGE TUBE DIAMETERS

Resist troublesome clogging.

18-MONTH WARRANTY

Against seals leaking.

AVAILABLE IN CORROSION- RESISTANT MATERIALS

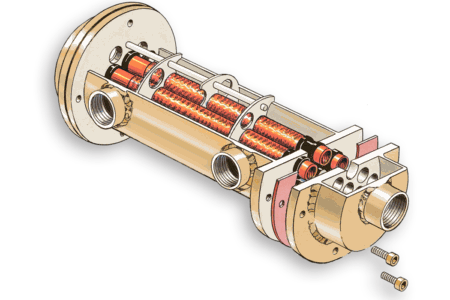

SYSTEM PROTECTOR™

ADDED SAFEGUARD FOR SYSTEMS UNDER CONTINUOUS OPERATION

The BOSS® (Brass Off Shore Service) is designed for equipment working in salt-corrosive environments. It features brass fining brazed to brass tubes. The mild steel framework is coated for offshore service; stainless steel framework optional.

BUILT-IN MESABI DEPENDABILITY WITH FLEXIBLE RUBBER SEALS TO ABSORB

THERMAL AND MECHANICAL STRESSES.

ALERTS OPERATOR TO LEAKING BY SIGHT GAUGE OR ELECTRONIC SENSOR.

COLLECTION CHAMBER ISOLATES FLUIDS AND CONNECTS TO DETECTION PORT.

ENVIRONMENTALLY-FRIENDLY.

Operating pressures*

Shell side: 150 psi (1000 kPa)

Tube side: 50 psi (350 kPa)

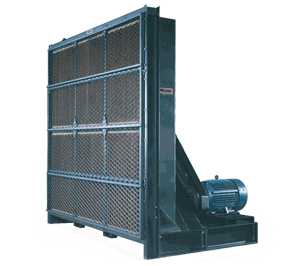

MESABI® CUBE™ COOLING SYSTEM

INCREASED COOLING PERFORMANCE

Featuring patented MESABI® S-Fin tube design combines industry-leading cooling performance with unsurpassed durability.

NO LEAKY SOLDERED SEAMS

MESABI® radiator rubber seals absorb vibration, shock and thermal expansion.

REPAIRABLE IN THE FIELD

Individual tubes allow for easy in-field repair to minimise downtime.

FULLY CUSTOMIZABLE

No cookie cutter solutions. Work directly with L&M. engineering to meet the exact needs of your operation. Ask us about our low noise options.

INDUSTRY’S BEST WARRANTY

We protect the industry’s best cooling system with the industry’s best warranty.

MAXIMUM SERVICEABILITY

Minimal maintenance design features clean out access door for easy and effective cleaning from the inside of the system.

Footprint reduction

Flexible design and robust construction

Need more information? Call us on +61 8 9230 4400 to speak with one of our experts.